How to install socket boxes in pocket doors

In the world of construction and interior design, the challenges of working around pocket doors to fit electrical socket boxes seamlessly into walls have long been causing headaches for professionals.

Traditionally, the lack of sufficient space in a pocket door to accommodate an electrical back box is a recurring issue. It not only complicates installation but also poses the risk of door damage or cable entanglement. The conventional approach often demands the construction of additional stud walls, escalating both material and labour costs.

Envo Slide was designed with these challenges in mind. Read on to learn how this innovative pocket door system solves existing problems...

Tailored for Socket Boxes

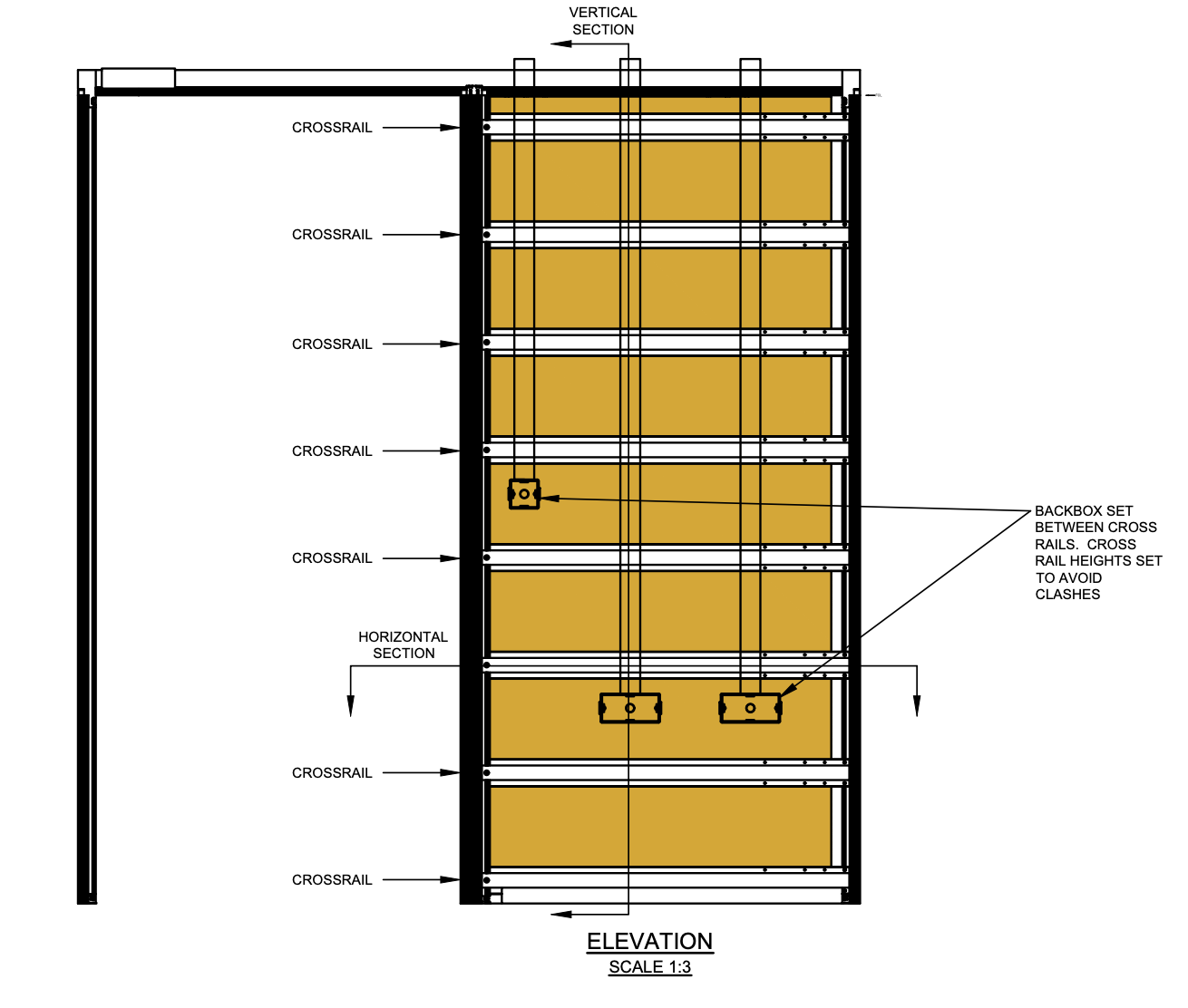

Designed with adjustable height cross rails, Envo Slide enables effortless placement of sockets and switches to ensure precise alignment and optimal functionality.

Minimalist Design, Maximum Efficiency

Only two layers of plasterboard are required to accommodate a 35mm back box. This streamlines the construction process, saving time and reducing material expenses.

Eliminating the Need for Additional Stud Work

One of the most helpful features of Envo Slide is its ability to bypass the necessity for additional stud walls. Instead, installers can simply add an extra layer of ply or plasterboard, simplifying the installation process without compromising structural integrity.

Innovative Cable Management

Envo Slide considers both safety and functionality, by incorporating a unique cable channel. This solution protects the cables from damage, as well as mitigating any risk of them becoming entangled or caught on the doors.

To discover more about the Envo Slide pocket door system, contact us on +44 (0) 208 253 9342, or email info@envo.co.uk. You can also access our Electrical Socket Detail PDF via our downloadable resources here.